Sumved International is well-known Reciprocating air compressors/Piston Compressors distributors, suppliers & exporters in Mumbai, India. These CompAir piston compressors are built for demanding tasks in automotive and machine shop environments, on production lines, in construction and woodworking shops, as well as in dry cleaning businesses, car wash facilities, and various agricultural uses.

Reciprocating air compressors, referred to as piston air compressors, are positive-displacement devices that utilize a crankshaft-driven piston and cylinder to compress air. Series of air volumes are enclosed in a limited area, raising this air to increased pressure. The reciprocating air compressor achieves this by employing a piston inside a cylinder as the element for compression and displacement. A major benefit of utilizing reciprocating compressors is that their installation costs are generally lower at the outset. Additional advantages of utilizing reciprocating compressors consist of:

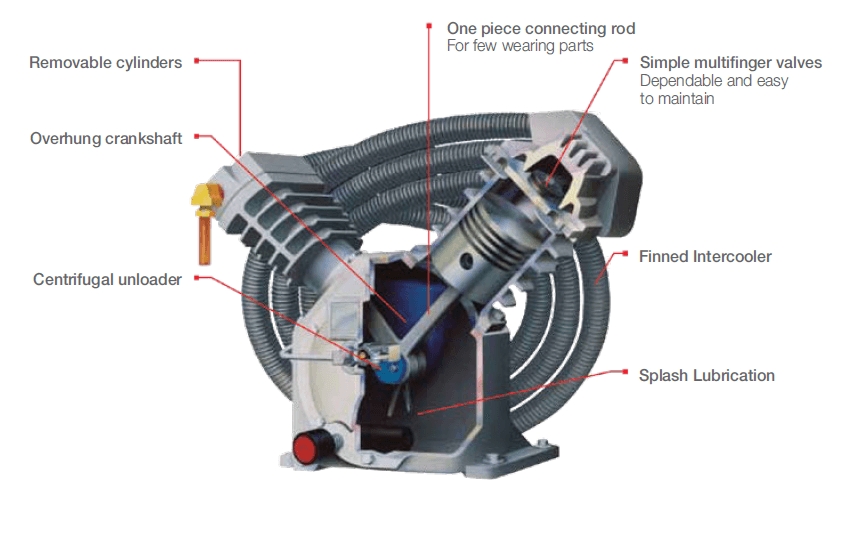

A two-stage model (1) compresses air to an intermediate pressure in the initial stage, (2) dissipates heat of compression via an intercooler, and (3) compresses air to a final pressure in the subsequent compression stage. Compressors with two stages are more efficient and are typically utilized for pressures exceeding 100 PSI, reaching a maximum of 175 PSI.

No other Reciprocating Compressor provides these economical, efficiency-enhancing attributes:

A long-lasting cast iron pump that delivers over 15,000 hours of reliable performance.

A completely copper finned intercooler reduces operating temperatures and increases pump lifespan.

A crankshaft that extends beyond its support and a one-piece connecting rod provide access to the drivetrain for convenient upkeep.

Individually cast cylinders allow for flexible and more cost-effective maintenance, focusing on one cylinder at a time instead of servicing the whole pump.

Engineered for intensive shop or industrial applications, CompAir Two-Stage electric air compressors deliver the quality and performance suitable for a wide range of uses and users, such as: auto service and body repair shops; fleet upkeep, machine workshops; manufacturing and production lines, construction; woodworking shops; dry cleaning establishments; car wash facilities; maintenance/repair shops, and agricultural operations.

Affordably priced, CompAir Two-Stage Value Packaged air compressors are ideal for automotive, commercial, or light industrial uses where a reliable air source is necessary. The value package consists of additional features such as a mounted and wired starter, automatic start/stop pressure switch control paired with an appropriately sized receiver tank.

| Model | Moter | Free Air Delivery | Pressure in psig | Air Receiver | Starter Type meter | Control |

|---|---|---|---|---|---|---|

| hp | cfm | rated | liter | |||

| GD 2340F 3 | 3 | 8.65 | 175 | 150 | Direct Online | Automatic Start-Stop |

| GD 2475C 5 | 5 | 13.99 | 175 | 225 | Direct Online | Automatic Start-Stop |

| GD 2475C 7.5 | 7.5 | 17.77 | 175 | 225 | Direct Online | Automatic Start-Stop |

| GD 2545D 7.5 | 7.5 | 24.18 | 150 | 300 | Direct Online | Automatic Start-Stop |

| GD 2545D 7.5 | 7.5 | 24.18 | 150 | 300 | Direct Online | Constant Speed Control |

| GD 2545D 10 | 10 | 30 | 175 | 300 | Direct Online | Automatic Start-Stop |

| GD 2545E 10 | 10 | 30 | 175 | 500 | Direct Online | Constant Speed Control |

| GD 2545E 12.5 | 12.5 | 35 | 175 | 500 | Automatic Star Delta | Automatic Start-Stop |

| GD 7100E 15 | 15 | 42.91 | 125 | 500 | Automatic Star Delta | Automatic Start-Stop |

| GD 15TE 20 | 20 | 59.8 | 125 | 500 | Automatic Start-Stop | Constant Speed Control |

| GD 15TE 25 | 25 | 79.2 | 125 | 500 | Automatic Start-Stop | Constant Speed Control |

| GD 15TE 25 | 25 | 79.2 | 125 | 500 | Automatic Start-Stop | Automatic Start-Stop |

CompAir Reciprocating multi-stage high-pressure air compressors are engineered for high-pressure uses. These compressors feature exceptionally robust components and are engineered for minimal upkeep and optimal performance. High pressure air compressors find extensive application in power generation facilities, the PET blow molding sector, the military, diving operations, and component testing.

| Model | Motor | Free Air Delivery cfm at Working Pressure | |

|---|---|---|---|

| hp | 350 psig | 500 psig | |

| GD 7T2 Package | 12.5 | – | 21.6 |

| GD 15T2 Package | 20 | – | 37.7 |

| GD 15T2 Duplex Package | 40 | – | 75.4 |

| GD 15T Package | 20 | 50 | – |

| GD 15T Duplex Package | 40 | 100 | – |

Our Single-Stage electric air compressors are perfect for the majority of professional compressor users. Every air compressor is built with robust cast-iron materials, designed for 100% continuous duty cycle to handle the most demanding tasks and provide prolonged pump life for years of reliable performance.

| Model | Motor | Piston Displacement | Maximum Working Pressure | Air Receiver Option | ||

|---|---|---|---|---|---|---|

| hp | m³/hr | cfm | bar | psig | litre | |

| GD SS1 | 1 | 6.99 | 4.12 | 8.62 | 125 | 100 |

| GD SS2 | 2 | 14.01 | 8.25 | 8.62 | 125 | 150 |

| GD SS3 | 3 | 23.36 | 13.75 | 8.62 | 125 | 150 |

| GD SS3 - 1 Phase | 3 | 23.36 | 13.75 | 8.62 | 125 | 150 |

The piston or reciprocating compressor includes a piston, intake and exhaust valves, along with a cylinder that has a proper cooling system, a connecting rod, and a crank. The operation is identical to the compression stroke in two-stroke engines. A single-stage reciprocating air compressor performs compression in one stroke, while a two-stage reciprocating air compressor carries out compression in two strokes and is made up of two cylinders.

The fundamental operation of a reciprocating air compressor, also known as a piston air compressor, involves using pistons powered by a crankshaft to compress air at elevated pressure. The initial stage of this process involves the piston in the reciprocating compressor moving back and forth within the cylinder by means of a rotating shaft, called a crankshaft, that utilizes a connecting rod to transform rotary motion into reciprocating movement. A motor or an engine supplies the energy needed to turn the crankshaft. The cylinder comes equipped with suction and discharge valves. A suction valve allows air to enter the cylinder, while the outlet releases the air after it has been compressed. The valves need to operate in sync to create compressed air.