Sumved International is a distributor, supplier, and exporter of Jindal Airline Piping solutions located in Mumbai India. totally devoted to quality, thus offering the best Jindal airline pipes for the aviation industry which has high standards in terms of pipe quality. In this connection, the comprehensive line of piping solutions is aimed at achieving top performance, durability and safe operation for versatile applications in the air transports. Thus, at Sumved International, we ensure that customers are satisfied with the service, price, and delivery time offered by making ourselves a leading pipeline company. Discover our products and services as well as the quality difference that we offer.

Jindal group holds the title of the top producer of ERW Pipes. highly varied in multiple piping systems like PE-AL-PE Pipes, also referred to as Multi Layered Composite Pipes or…. Jindal MLC Pipes, PVC Pipes, UPVC Pipes, and HDPE Pipes are available. and pipes made from CPVC. These pipes have multiple uses. uses like providing Hot & Cold Water, and Waste removal, Supply of water for irrigation, supply of water from borewells, and provision of gas. System of distribution.

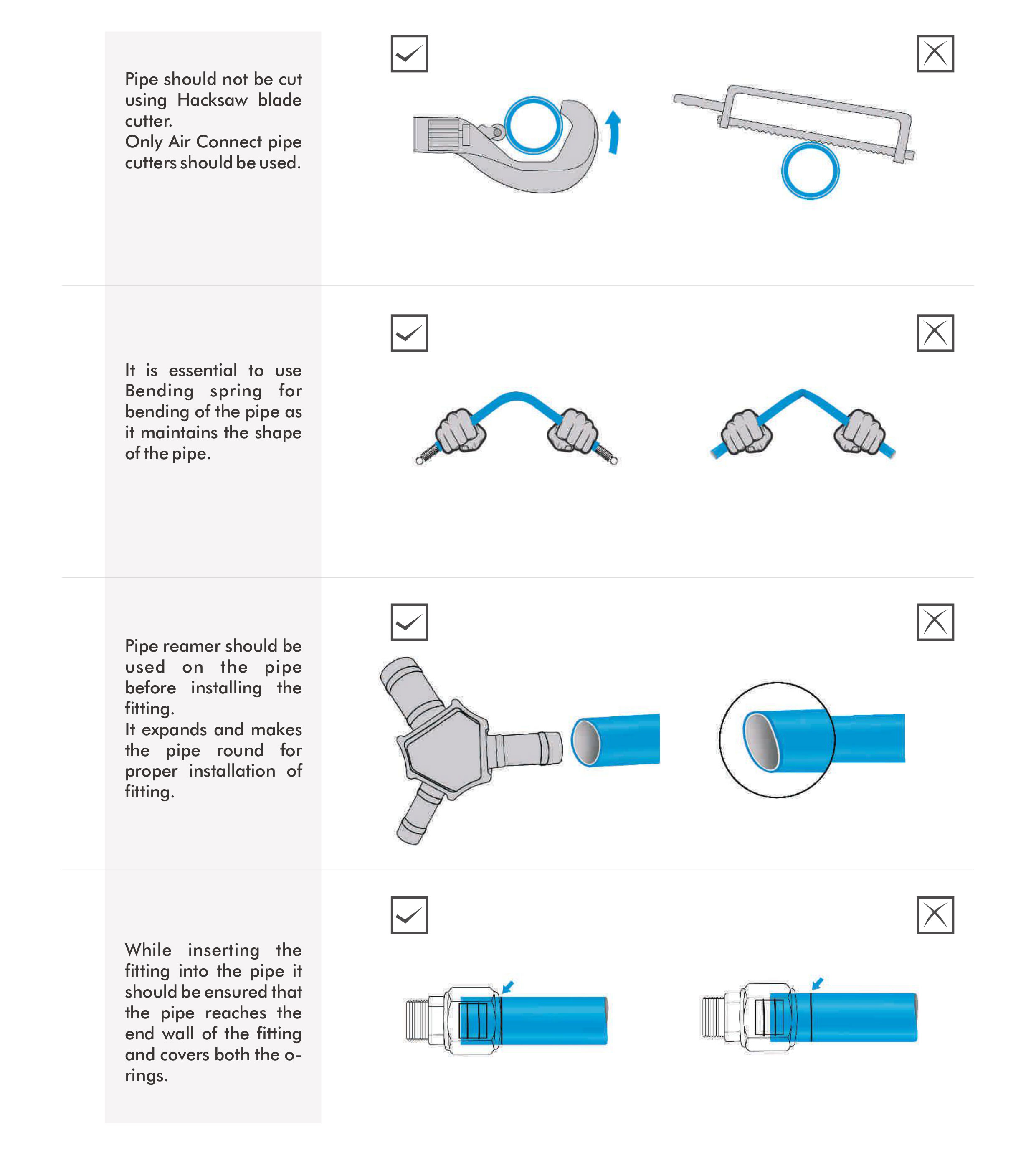

The Air Connect Piping system consists of layers that are stacked on top of each other. composite tubes and various types of connectors. The Brass and Plastic materials are available for the fittings. and are connected using either compression method or crimping methodology. This offers the customer a range of choices. select from based on their budget, need and software program.

| Fluids |

Compressed Air Vacuum Inert Gases (argon, nitrogen) |

|---|---|

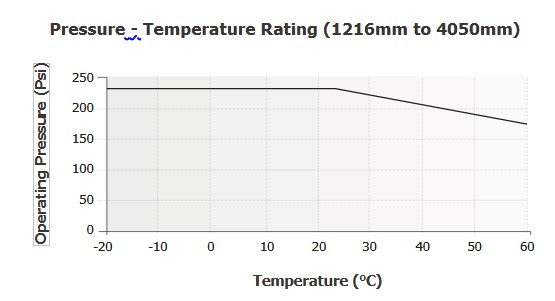

| Maximum Working Pressure |

232 Psi at 23°C 175 Psi at 60°C |

| Working Temperature Range | -20°C to 60°C |

|---|---|

| Thermal Conductivity | 0.45 W/m.k |

| Co-efficient of Thermal Linear | 25 x 10-6 m/m.k |

| Expansion Minimum Burst Pressure | 870 psi - 507.5 psi (depending on Pipe size) |

| Long Term Hydrostatic Strength | 391.5 psi - 290 psi (depending on Pipe size) |

| Resistant to |

Thermal Variations Corrosion Mineral and Synthethic Compressor Oils Fire |

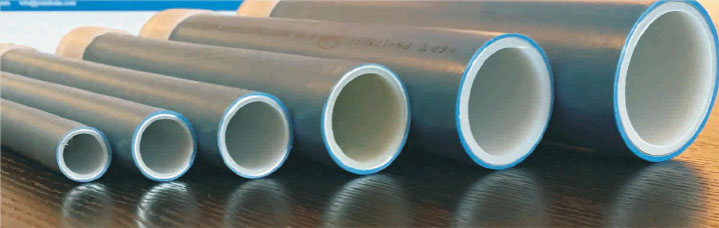

| Outside Diameter (mm) | Wall Thicknes (mm) | Aluminum Layer | Inner PE Layer | Outer PE Layer | |||

|---|---|---|---|---|---|---|---|

| Pipe Size | Nominal | Tolerance | Nominal | Tolerance | Thickness | Thickness | Thickness |

| (mm) | (mm) | (mm) | |||||

| 1216 | 16 | 0.3 | 1.65 | 0.4 | 0.2 | 0.9 | 0.4 |

| 1620 | 20 | 0.3 | 1.9 | 0.4 | 0.25 | 1 | 0.4 |

| 2025 | 25 | 0.3 | 2.25 | 0.5 | 0.25 | 1.1 | 0.4 |

| 2532 | 32 | 0.3 | 2.9 | 0.6 | 0.3 | 1.2 | 0.4 |

| 3240 | 40 | 0.3 | 3.85 | 0.6 | 0.3 | 1.7 | 0.4 |

| 4050 | 50 | 0.3 | 4.35 | 0.6 | 0.3 | 3 | 0.4 |

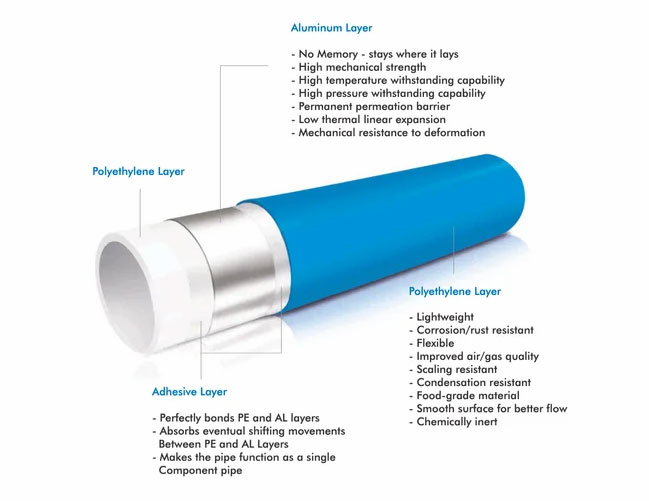

Air Connect Pipes are made up of both an inner and outer layer. Polyethylene's external layer is enclosed by another layer. aluminium center. All the layers are fixed for good united by a middle layer of Adhesive made from polyethylene. The central part made of aluminium is securely closed using Over-lap welding method allows the pipes to endure high operational demands stresses and strains.

The Polyethylene layer plays a significant role. 30% of the pipe's total strength The Aluminium layer accounts for the remaining 70%. That is a flexible tube that is packaged in coils of up to 200 meters, leading to a significant decrease in the quantity of. connections like couplings and fittings forearms.