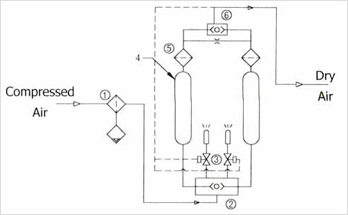

We are India's top Dyspell Desiccant Air Dryers Distributors, Traders & Exporters in Mumbai, India. These are air dryers that work through the help of a desiccant material to remove water vapour from compressed air. This desiccant is basically a material that has an enormous tendency to conquer the water molecules therefore it can simply accept and hold on moisture from air transporting through dryer. Some Examples of Adsorbent Type Dryers. Two towers filled with desiccant material While one tower is online drying the air, it also needs to regenerate (or dry out) for an ongoing supply of dried air.

| Maximum Working Pressure | 16 kg / cm2. |

|---|---|

| Air Inlet Condition | Maximum Fluid Temperature 45oC. |

| Pre-filter rating | 0.3 Microns (Coalescer). |

| Cycle Time | 4 Minutes. |

| Regeneration Volume | 10% |

| Air Outlet Conditions | Dry air at - 40oC Dew Point. |

| Operating Voltage | 85 - 265 V 50 / 60 hz l Ph. |

| Model | Flow cfm | End Connection BSP | Dimensions (mm) | Weight Kgs | Recommended Accessories | |||

|---|---|---|---|---|---|---|---|---|

| Height | Width | Depth | Pre filter (1) | Post filter (2) | ||||

| Dryspel 5 | 5 | 1/2" | 390 | 280 | 200 | 9 | G 24 P | G 24 Y |

| Dryspel 10 | 10 | 1/2" | 600 | 280 | 200 | 11 | G 24 P | G 24 Y |

| Dryspel 20 | 20 | 1/2" | 1015 | 280 | 200 | 16 | G 100 P | G 100 Y |

| Dryspel 30 | 30 | 1/2" | 810 | 350 | 260 | 28 | G 100 P | G 100 Y |

| Dryspel 45 | 45 | 1/2" | 1055 | 350 | 260 | 34 | G 100 P | G 100 Y |

| Dryspel 60 A | 60 | 3/4" | 1250 | 350 | 285 | 43 | G 100 P | G 100 Y |

| Dryspel 100 | 100 | 1" | 1540 | 415 | 300 | 81 | G 250 P | G 250 Y |

Pre-filter, Inlet shuttle valve, Exhaust valve, Desiccant tower, After filter, Outlet shuttle valve