We offer a comprehensive range of products, designed to meet specific needs of

industries:

Sumved International stands as a trusted distributor, supplier, and exporter of premium ARO air-operated diaphragm pumps, offering an extensive range of solutions to meet diverse operational needs. Some of the great product offerings are ARO air-operated diaphragm pumps recognised for durability, performance, and applicability. ARO’s authorised partner aims to offer our customers the best quality of diaphragm pumps possible, and their performance in different industries is guaranteed. By ensuring that the clients are offered the best services in addition to their specialised knowledge of ARO diaphragm pumps, Sumved International has remained a prominent supplier that offers the highest quality services each time clients make a transaction.

Josts Counterbalance Electric Forklift:

| Minimum Order Quantity |

1 Unit |

| Power Source |

Air Operated |

| Pump Type |

Air operated Diaphragm Pump |

| Material |

Stainless Steel,PTFE |

| Max Flow Rate |

1401 Lpm |

| Brand |

INGERSOLL-RAND ARO |

| Phase |

Air Operated |

| Color |

Black |

| Voltage |

220-240 V |

| Maximum Discharge Flow |

1041 Liters |

| Discharge Pressure |

8.6Kg/sec |

| Frequency |

50 - 60 Hz |

What is air operated diaphragm pumps?

An air-powered dual diaphragm pump is a device powered by air that controls compressed air flow to alternate between two pump chambers.

Air-operated diaphragm pumps have the capability to move liquids of various viscosities, including those containing suspended solids. They are able to withstand various aggressive chemicals like acids due to their ability to be made using different body materials and diaphragms.

How does an air operated diaphragm pump work?

AODD pumps employ two flexible diaphragms that are connected to a common shaft that reciprocates in strokes to draw and expel fluids into AODD’s fluid chamber. This movement draws fluid through an inlet port; thereby making it an inlet movement.

When the diaphragms are then inactivated and snapped back to their position using compressed air, the fluid comes out of the product chamber through an outlet port. This action continues until the AODD is working, and this action is responsible for the pumping motion for which this equipment is famous.

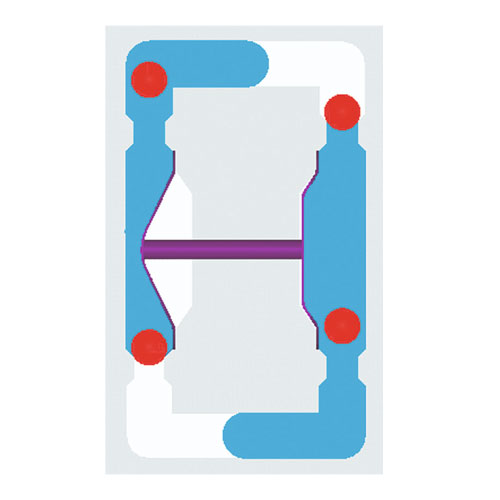

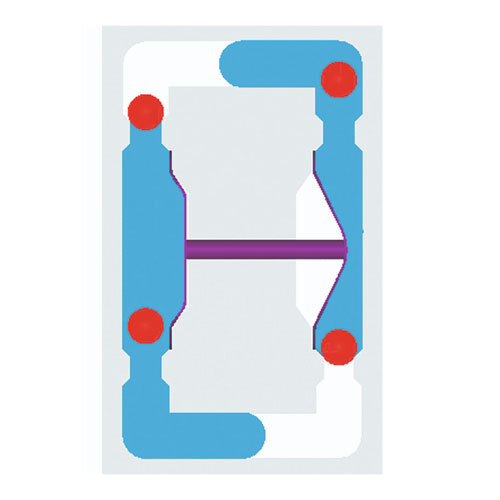

In Figure 1, the left diaphragm has been pushed to the direction of the fluid chamber and in the process the liquid has been ejected through the fully opened valve at the apex of the discharge vent. At the same time, right diaphragm draws into right and hand chamber a certain quantity of liquid. The movements are performed as indicated above and at the end of the stroke the positions of the rowers and the scullers will be exchanged as illustrated in figure 2 above.

What is air operated diaphragm pumps used for?

AODD pumps are commonly used in various applications as versatile workhorse devices.

- Mining involves removing water from both above and below ground locations and quarries, as well as moving sludges and slurries and transferring fuel for vehicles and heavy construction machinery.

- Pottery - applying ceramic coatings, transferring from the day tank, pouring into molds

- Chemical handling - transferring chemicals in and out of tankers, using a portable utility pump, measuring out chemicals for batching or dosing.

- Electroplating and anodizing - replenishing chemicals in plating or metal finishing tanks, stirring cleaning solutions, and filtering are important processes.

- Pulp and Paper industry - inks for printing, adhesives for bonding, large-scale adhesive application.

- Oil and Gas - equipment for filtering press, transferring bulk fuel, and transferring settling pond.

- Water treatment and wastewater treatment - involve the movement of suspended solids using a filter press and a utility pump.

What benefits do air operated diaphragm pumps offer?

AODD pumps provide several benefits, specifically:

- AODD pumps reduce diaphragm wear more than mechanically driven pumps because compressed air helps balance pressure. This indicates AODD pumps can operate for extended durations without harm and also have a longer lifespan.

- Their design enables complete separation of fluids and delicate components, leading to decreased repair frequency.

- They are capable of managing rough and thick sludges, slurries or fluids. Additionally, the pump's gentle pumping system makes it ideal for fluid applications that are sensitive to shear.

- Due to their lack of spark-producing working mechanisms, AODD pumps are appropriate for use in potentially dangerous locations with flammable materials.

- If the diaphragms in AODD pumps do not fail, then there will be no leakage because they are the only seals between the wetted components and the exterior.

How to repair an air operated diaphragm pump

If your AODD pump fails, make sure to inspect the following:

- Make sure the air inlet size is not too tiny.

- Examine the icing on the pump's muffler. AODD pumps produce a lot of noise while running, which is why mufflers are frequently employed. Due to the compression of air in the device, the muffler's temperature may occasionally drop below freezing. In very moist conditions, this could result in the accumulation of ice. Icing is especially common with rival pumps. ARO EXP Series diaphragm pumps are designed with expertise to ensure no ice formation by utilizing patented quick-dump valves that release cold air outside, preventing freezing.

- Inspect the inlet and outlet lines of the pump for obstructions, including valves that are fully or partially closed.

- Frequently check the AODD pump for any signs of leakage. During regular pump upkeep, make sure to change out any PTFE O-rings that may be prone to leaking.